Environment

Environmental philosophy and policy

Uchiyama Group Environmental Philosophy

To protect the environment, the Uchiyama Group will work as a whole to produce and improve our products in harmony with beautiful nature.

Uchiyama Group Environmental Policy

The Uchiyama Group will promote the following items in order to provide products and services that satisfy our customers and reduce the environmental impact of our corporate activities.

(1)We will strive to effectively use limited natural resources, promote energy-saving activities, and incorporate the 3R(Reduce,Reuse,Recycle. We will also continue to investigate and reduce the use of substances of concern in our products. We will continue to reduce environmental impact and promote activities that strive to prevent pollution.

(2)Comply with relevant environmental laws and regulations and make necessary arrangements to work with customers and neighboring communities.

(3)Continuous improvements will be made through regular internal audits and review of the environmental management system.

(4)This environmental policy is described in the Environmental Management Manual and is available to all members of the Uchiyama Group in an effort to raise awareness of the environment.

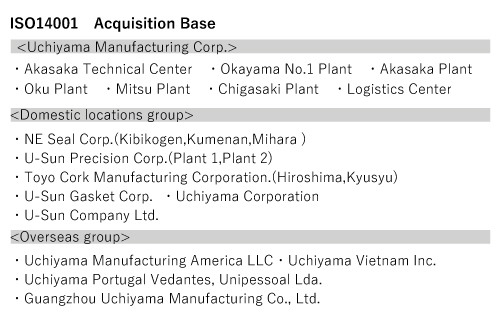

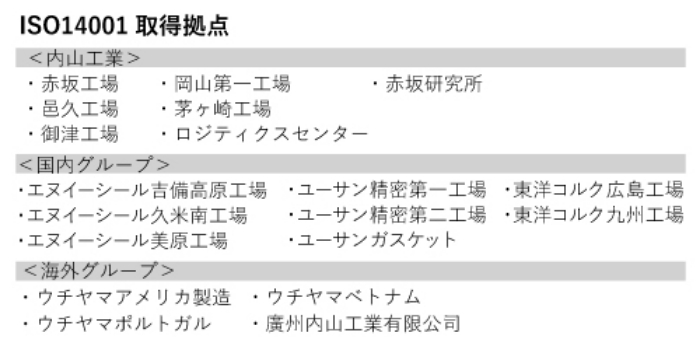

Environmental management system (ISO14001)

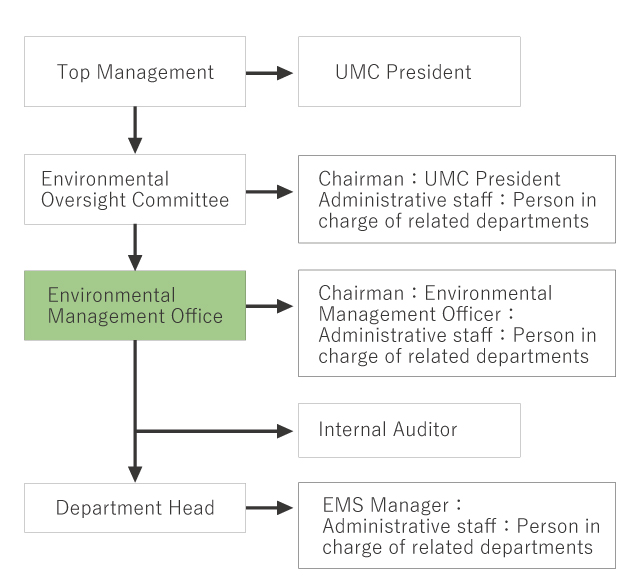

ISO14001 operation management system

We have organized a ISO14001 operation control system the chief officer. Activities to realize a sustainable society, such as reducing CO2 emissions, have become active, and we are working together to respond to increasingly growing demands for corporations.

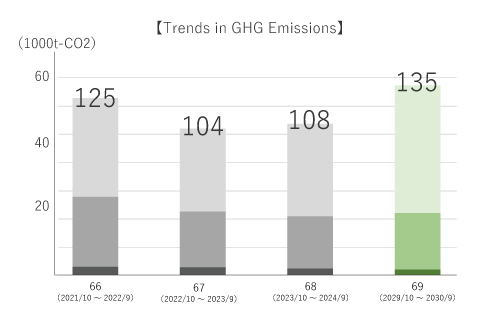

Long-term Environmental Targets and Results

The Uchiyama Group has set a target of virtually zero emissions in 2050 by reducing emissions of GHG (greenhouse gases) by 3% every year, based on the 66th fiscal year (2021/10 to 2022/9). From SCOPE1 to 3, we will reduce GHG emissions in all processes associated with our business activities.

Development Initiatives

Of the material

Development

In order to reduce risks to the environment and achieve a sustainable society, the Materials Development Division is creating environmentally friendly materials using biomass-derived materials. As it is a material used in automotive products that preserve the lives of people, we are developing high-quality materials that are not only environmentally friendly but also satisfy strict evaluation standards.

Manufacturing Efforts

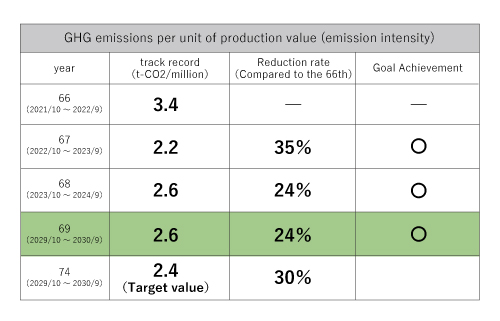

In order to carry out production activities efficiently without waste, we are constantly working on activities that are conscious of improving productivity. On the production line, we are pursuing improvements in productivity on a daily basis, such as by changing programs to reduce cycle time.

Reduce material scrap.

We are constantly working on activities that are conscious of improving productivity. We are pursuing improvements in productivity on a daily basis, such as by changing programs to reduce cycle time.

Procurement initiatives

Of the material

Procurement

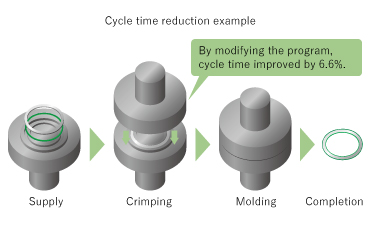

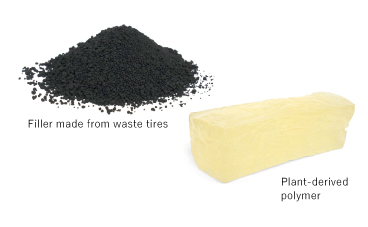

To develop environmentally friendly products, we are promoting the procurement of biomass materials. We procure fillers made from waste tires as raw materials (upper left of photograph) and polymers made from plant-derived materials (lower right of photograph), etc., and utilize them for product development.

Procurement

Uchiyama Industries manufactures products made from cork, such as cork plugs and cork floors. Cork is sampled from the bark of cork oak, which regenerates in about nine years. It is a material suitable for environmental maintenance, which absorbs a large amount of CO2 during the regeneration of bark. We indirectly contribute to the environment by procuring cork and making it a product.

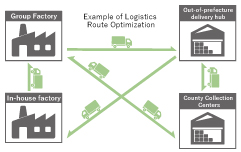

Logistics Initiatives

Optimization

By optimizing the route from our company and group factories to collection points within the prefecture—previously covered by three trucks—to a more efficient route including delivery points outside the prefecture, we reduced CO2 emissions from product transportation by approximately 73 tons per month. *Measured using the improved ton-kilometer method

Efforts in general

Energy

Introduction

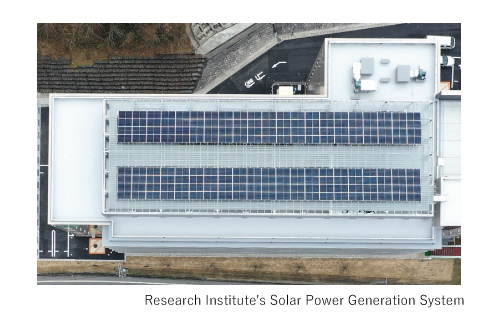

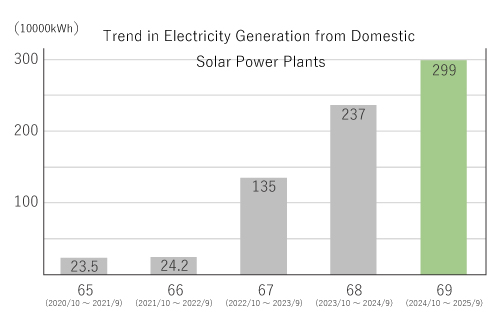

Solar power generators are installed on the rooftops of laboratories and factories to provide a portion of the power consumed for business activities. We are promoting the introduction of renewable energy throughout the Group.

Electricity

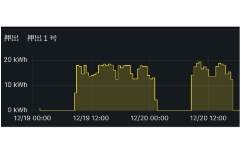

To reduce unnecessary power consumption in production activities, we are advancing power measurement and visualization by production area. Power usage is displayed graphically over operating hours, serving as reference data for identifying causes of wasteful power consumption and implementing efficient improvement activities.

Activities to reduce

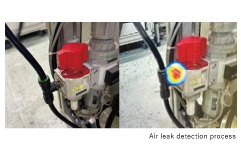

To reduce energy loss, each plant is working to decrease air leakage from its compressors. In addition to auditory checks, we have introduced equipment that detects areas where air leaks occur with sensors to conduct efficient activities.

Each plant is equipped with wastewater treatment facilities that discharge wastewater that meets standards set by local governments or laws. Since the quality of wastewater after treatment is stable, some facilities have living fish on-site.

Reduction

We strive to establish a recycling-oriented society by promoting 3R(Reduce,Reuse, Recycle) through the efficient use of our resources. We are working to reduce environmental impact by developing products made from rubber waste generated in the course of production, and by purchasing metal parts as recyclable resources to promote recycling.

日本語

日本語