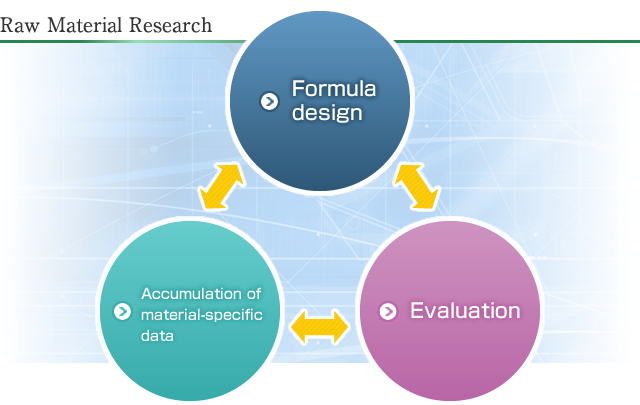

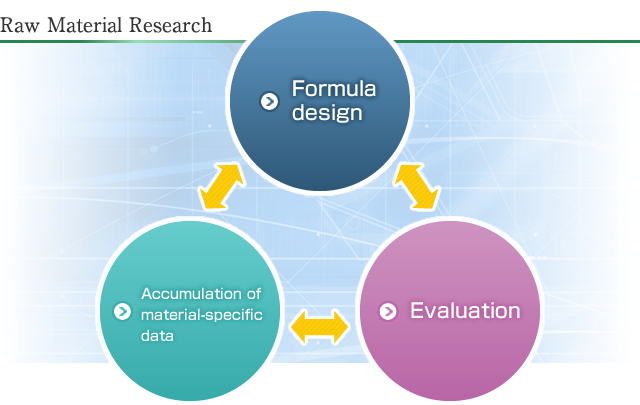

Thorough research of raw materials is the first step to produce high-quality automobile parts. The best raw materials, most suitable for varied requirements, are born by repeated testing with state-of-the-art equipment.

Formula design

| Rubber Kneading |

| We mix a variety of chemicals and knead rubber to satisfy our customers’ requirements. |

Accumulation of material-specific data

We have more than 100 formulations to meet customers’ requirements such as heat-resistance, oil-resistance, and low temperature. Also, short-time development is made possible for newly-arising needs by applying past data of mixing design.

Evaluation

| Micro-infrared spectroscopic meter |

| Evaluate the substances in gaskets & seals at a micro-level, and make use of high technology materials. |

| Universal tension, compression tester |

| A tensile, compressive performance may be evaluated under numerous conditions of temperature, humidity, ultraviolet rays, and the like. |

| Tension measuring instrument |

| This evaluates the tension of rubber products like a rubber gasket. |

| Gas chromatograph |

| Continually identify various kinds of materials and grasp the latest market trend. |

| Direct current magnetization characteristic testing equipment |

| It checks magnetic characteristic of magnetic materials which is required to magnetic encoder transmitting rotation signal of ABS. |

| Differential scanning calorimeter |

This uses a small sample of the material to measure its low-temperature performance as well as its melting point.

|

| Friction abrasion testing equipment |

| A test piece is used to measure friction and abrasion resistance which are required for bearing seals. |