Repeated severe testing is conducted on UCHIYAMA’s product development for various required conditions from the raw material stage. In response to market demands for reliability, fuel economy, electronization, and cost reduction, UCHIYAMA develops and produces various gaskets and sealing products. Our products can withstand long and severe operating conditions. Preventing “leakage” is a fundament of your product development. Making full use of UCHIYAMA’s advanced technology to completely shut off leakage of heat, fluid, gas, etc., we continue to meet the challenges of high-quality product making.

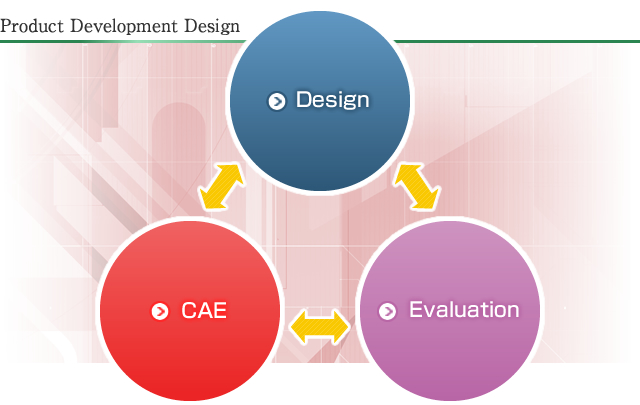

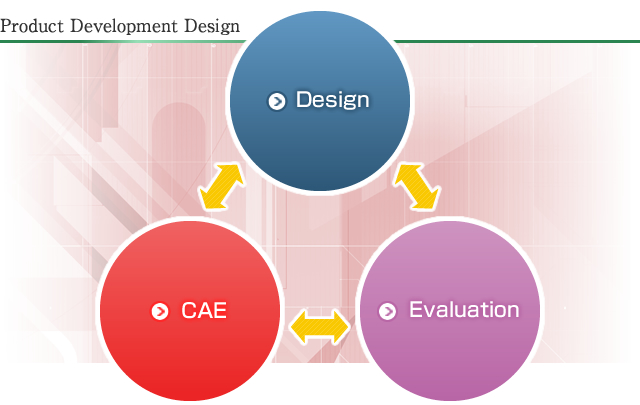

CAE

| Demo 1: Gasket model |

It performs simulation two-dimensionally and three-dimensionally, and reflects rubber deformation volume and counterforce on product design.

|

| Demo 2: Seal model |

A heavy load simulation is used to calculate rubber and load deformations. The information obtained is then incorporated into product design.

|

Design

| CAD |

| Full use is made of a computer so as to design the optimum shape in consideration of the balance between the location used and the characteristics of material. |

| 3D printer |

| It molds a three-dimensional shape based on 3DCAD and 3DCG data. |

Evaluation

| Surface roughness measuring instrument |

| Sealing with gaskets and seals is accomplished by affixing them to a component. Since the roughness of the componentmaterial effects the seal performance, we measure the surface roughness in microns. |

| 3 Dimensional coordinate measuring machine |

| Detects 3 dimensional/coordinate values by measuring points and lines of products, jigs, and parts. |

| Digital microscope |

| A micro visual field is evaluated to detect any minute non-conformities or defects. |

| Vibration fatigue tester |

| It is unavoidable for automotive gaskets to deteriorate due to long-term vibration fatigue. This testing machine simulates long-term vibration fatigue and evaluates products. |

| Pressure analyzing system |

| The airtightness of gaskets is evaluated by analyzing whether tightening pressure is uniform through a pressure distribution image. |

| Thermal shock tester |

| Product evaluation is made under various temperature conditions. |

| Seal tester |

| Seals, used around wheels of a car, function in a severe environment such as mud and dust. This testing machine simulates that same environment and evaluates the seal performance. |

| Dynamo meter |

A device capable of reproduce an actual traveling state in which gaskets are mounted onto an actual engine. |

| Cooling water, oil circulation system |

| It circulates cooling water and oil under various heat loads. |

| Tactile sensor |

| Depicts surface pressure distribution in real time 2 and 3 dimensions. |

| Compound corrosion testing equipment |

| Seals which are used in tire rotating areas of a vehicle are exposed to harsh usage environments such as snow/ice-melting material. Using a process of repeated spraying with salt water and drying, this equipment evaluates rust-resistance of the products. |